On April 3rd 2023, to reflect the growth of our company, “Euro Heat Pipes” brand evolves […]

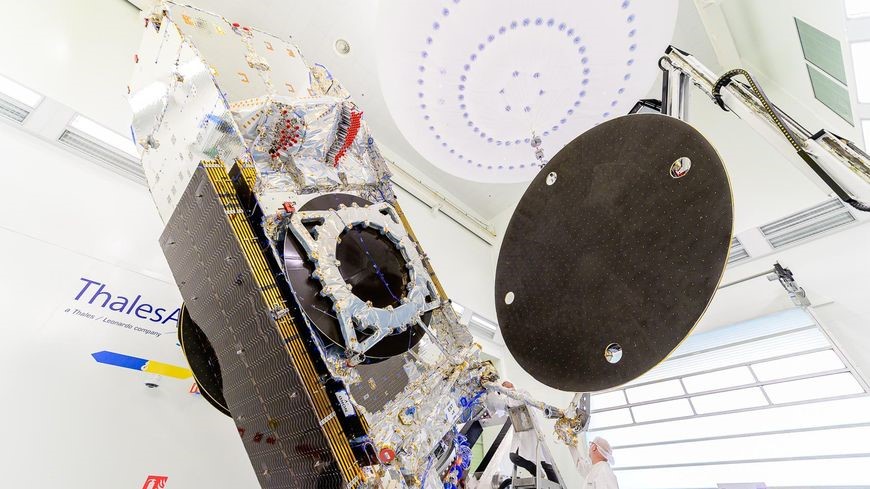

Manufactured by Thales Alenia Space, Konnect VHTS will lift-off from Kourou on the 7th of september […]

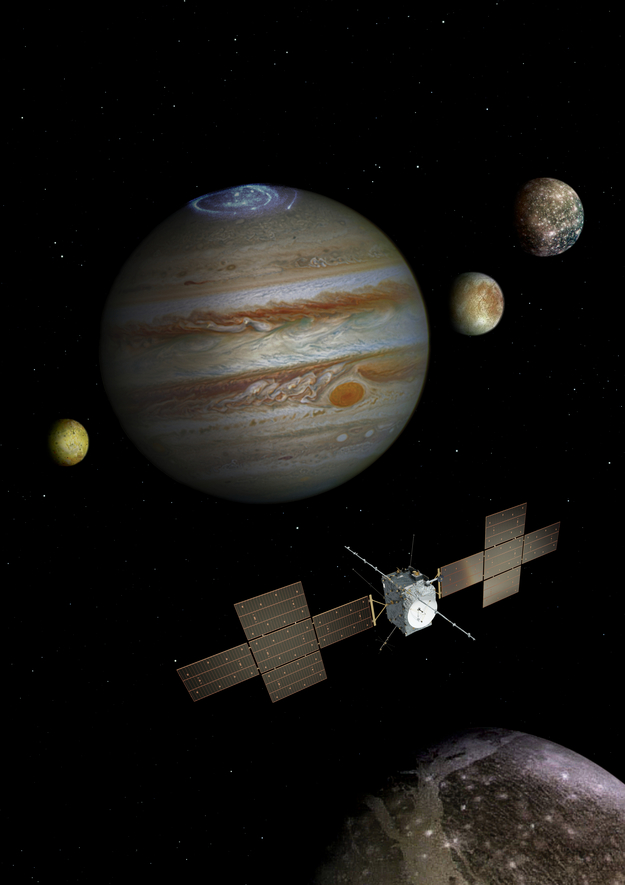

By Dominik LANG (OHB) & Olivier BERDER (EHP) Last news update from OHB, dated May 5, […]

Euro Heat Pipes work is quoted in the newspaper “l’Echo” in an article dedicated to the […]

EHP has completed its major TELECOM ARTES 4.0 project with ESA funds. Objectives The 3 mains […]

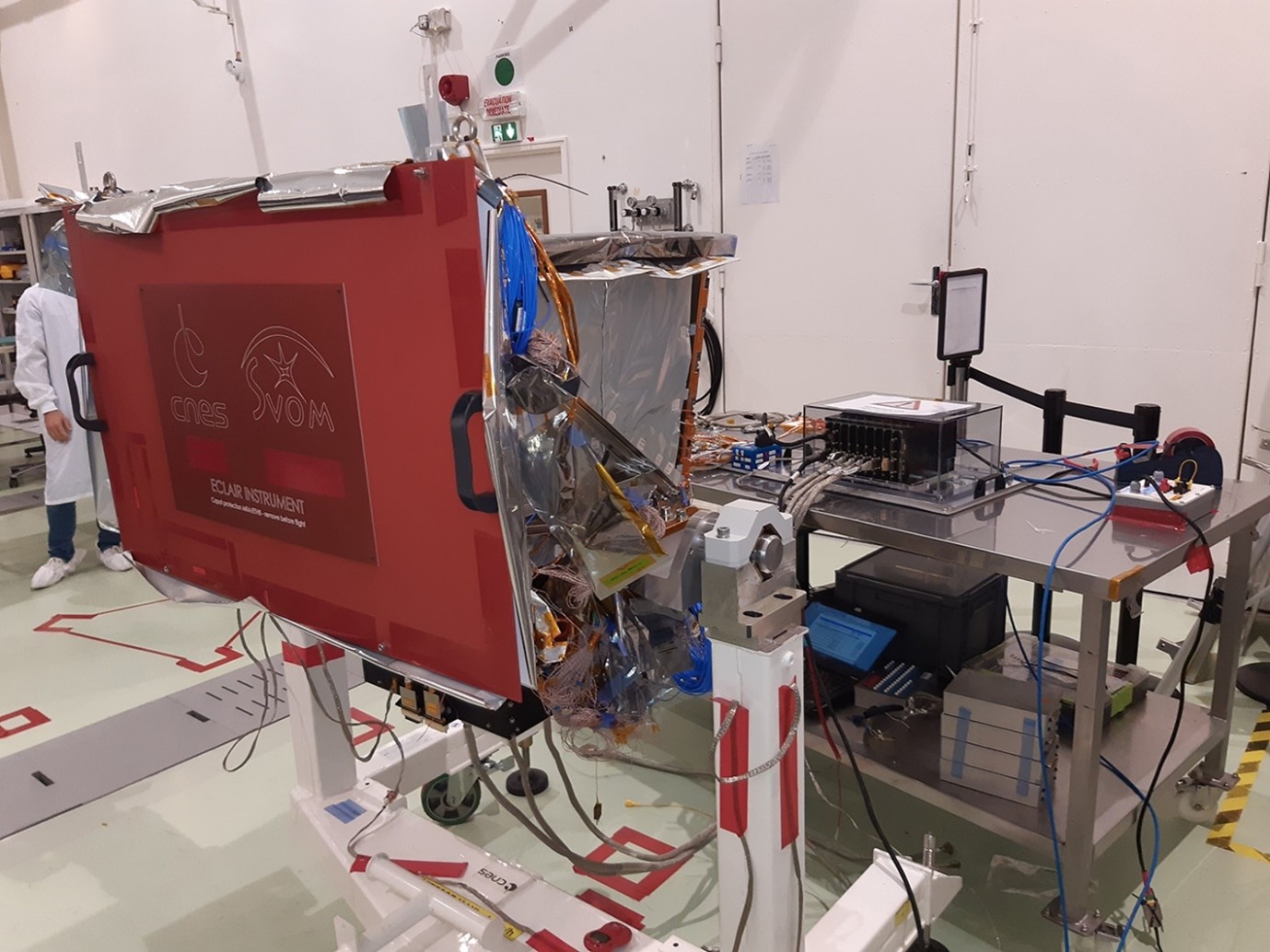

MXT and ECLAIRs instrument for Franco-Chinese satellite SVOM have finalized their assembly at CNES TOULOUSE. They […]

The SES-17 satellite was successfully launched into space onboard an Ariane 5 launcher operated by Arianespace […]

OneWeb Launch #11 (Flight ST36) is scheduled to depart 14 October at 6:40pm local time (5:40am ET / […]

[In French below] OneWeb : Mission accomplished ! In 2016, the OneWeb project started a new era for […]